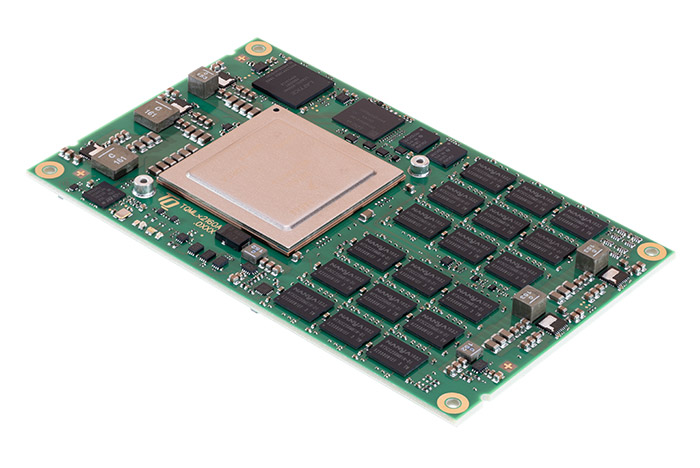

TQ receives the PCB Design Award 2020 for its embedded module TQMLX2160A from the professional association Elektronik-Design (FED)

Driving technology forward and thinking the step further - this is how the TQ-Group has distinguished itself for more than 25 years. Now the company and its layout developer Georg Scheuermann are celebrating the PCB Design Award 2020.

The jury, which only awards this special prize every two years, rated the design of the TQMLX2160A module as "outstanding in all areas - from complexity to execution". Last Wednesday, the layout department and company management were thrilled to accept the award.

from left to right Mr. Bornhorn, Mrs. Reel (FED), Mr. Walser, Mr. Scheuermann, Mr. Stahl, Mr. Schneider (TQ)Download image

It has always been technological challenges that drive and motivate the TQ-Group: Innovation, setting new standards and pushing technology - qualities that have been part of the daily spirit at the company headquarters in Seefeld in Upper Bavaria for more than 25 years.

Layout designer Georg Scheuermann has been with the company for over 20 years and represents exactly this mindset. Now, he and TQ can celebrate the PCB Design Award 2020 in the category "high wiring density, high transmission rates, HDI" for his design of the TQMLX2160A module. This is one of the highest awards in the electronics industry that the FED grants.

"This is ingeniously thought and ingeniously made" summarizes the jury of the FED in their laudation. The TQMLX2160A is a cleverly constructed 18-layer multilayer with a minimum number of crimping. It guarantees high speed demands and the optimal power supply for processor and memories. Georg Scheuermann is honored and comments: "It is always a long and hard way to get an award like this, because a lot of time and know-how goes into such a new development - but it was worth it and this award is a confirmation that we have succeeded in creating something special, which is certainly a benchmark in terms of functionality and size".

Robustness combined with maximum functionality and perfectly used space

On the 126 x 78 mm board 98 active and 1,734 passive components were placed on both sides and 9,651 connections were wired on 18 PCB layers; the processor alone has 1,517 connections. Of 8,310 pin-to-pin connections, 6,600 were routed using special rules such as lengths of the lines, pin pairs, match lengths and routing topology. A total of 28,797 drills (vias) were required for the routing. Microvias were used on the top and bottom PCB layer. Impressive figures, which were a real challenge in the layout at first. "The combination of extremely fast and steep-edged signals (24 x SerDes lanes with up to 25 GBit, 2 x USB 3.0) as well as the high currents (core supply up to 70A, DDR supply up to 30A, "auxiliary supplies" with up to 8A) were really a big task in this project", says Scheuermann. The routing of the high-speed interfaces had to be designed in such a way that no drop lines were created on the vias. A routing without any vias was not possible because the processor is placed on the top and the module connectors on the bottom.

Company management is proud and enthusiastic

"With this module, our developers have really succeeded in creating something very special, which currently represents the highest state-of-the-art technology," says Rüdiger Stahl, one of the two founders and managing directors of TQ-Systems GmbH. CEO Detlef Schneider is also excited about the performance of his employees: "This module and this award show that our employees develop products at the highest level, which help our customers to realize their product ideas. Thanks to its combination of size, function and robustness, this module offers the best conditions for future high-speed applications with high memory requirements - even in harsh environments".

Unless otherwise stated, TQ-Systems GmbH is the copyright holder of the images used in this press release. These pictures can be used free of charge if the author is named.